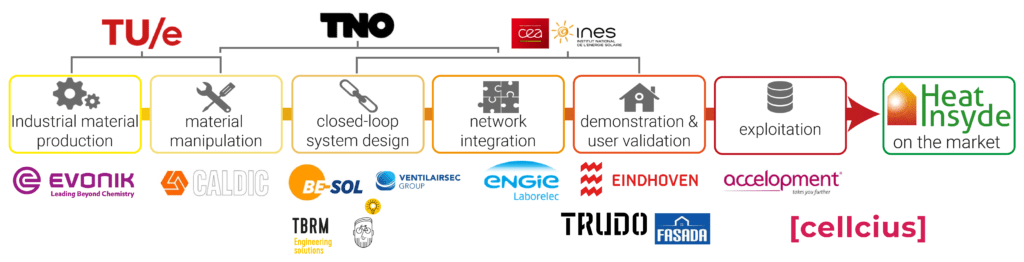

In July and October 2021 the HEAT-INSYDE consortium officially welcomed two new partners to the project that advances heat batteries for residential heating and electric systems, TBRM Engineering solutions and Cellcius B.V. Both based in the Netherlands, their involvement in the HEAT-INSYDE project is quite different.

Previously known as Segula Technologies Nederland B.V. established in 2010, as of June 2020 TBRM Engineering Solutions has become part of the TBMR group, a technology-driven investment and technical consultancy company. TBRM Engineering solutions, with their expertise in the analysis of thermal systems as well as innovative engineering and hardware solutions, contribute to the development of the thermochemical material module of the heat battery. This positions TBRM in the middle of the heat battery value chain to market, with a focus on the system design.

“We are happy to become a partner in HEAT-INSYDE and contribute with our expertise in engineering and manufacturing to make a success of the heat battery.”

Patrick Smulders, Chief Technology Officer at TBRM

Cellcius B.V., on the other hand, was founded in 2020 as a spin-off of TNO and TU/e. With its mission to accelerate the energy transition and to contribute to a more sustainable future, within the HEAT-INSYDE project, Cellcius is dedicated to bringing our solution to the market and closes the value chain with a strong role in the exploitation of the heat battery.

The technology of the HEAT-INSYDE battery makes it possible to store energy provided by heat sources like heat pumps, solar collectors, or heat networks. Thanks to the thermochemical material and the closed-loop system design, the HEAT-INSYDE battery can safely store such energy for later use in the form of heat, overcoming the gap between supply and demand of renewable energy. This reduces the need for expensive infrastructure and, with the help of the heat battery, the peak load in supply and demand of sustainable energy sources can be reduced.

Follow our social media channels on Twitter and LinkedIn to be kept up to date on the project’s latest progress!